Xerox Baltoro – a new platform for inkjet

The model choice for SRA3 based inkjet production printers is still quite limited, especially when compared to the choice in colour toner devices. While the sales of toner-based systems in high-end SRA3 are levelling off however, inkjet can extend the market by bringing its own strengths to the table, like: highest speeds, lower consumable cost – especially for low coverage – and a simplified marking engine. Inkjet will not make toner obsolete, but it will enlarge the scope of digital cut-sheet production presses noticeably.

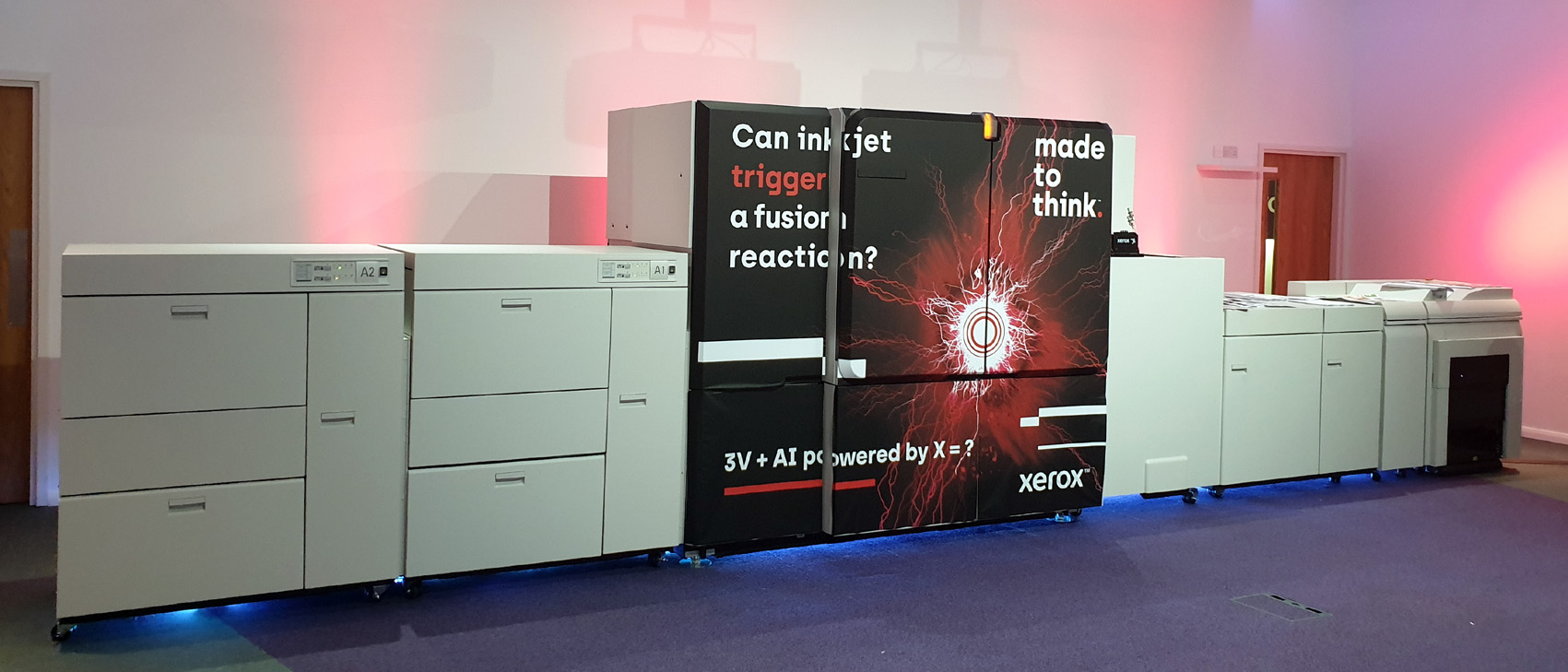

Accordingly, it should lift some eyebrows when Xerox is launching a new model with the Baltoro HF. It is not the first foray for Xerox, having launched the Brenva HD at drupa 2016. On the 17th of October 2019 the Baltoro was shown publicly in Europe for the first time after having had its launch in Rochester in June already. On the first appearance the Baltoro and Brenva look quite similar – both use the tried & tested paper transport of the iGen5. This includes a wide range of paper decks and in-line finishers, which become available for the Baltoro. The drier is a very compact NIR drier.

Xerox Baltoro at the Uxbridge Demo Centre

Speed is a strength of inkjet and hence eyes are on the running speed. The Baltoro has the same speed as the Brenva (after the 2018 speed upgrade) with 275 A4 images per minute in duplex. Using A3 paper increases the speed to 300 A4 ipm. Simplex speed is 50% lower. This might be down to the iGen paper transport not allowing for a faster paper pick or delivery. This is in a similar range as competing products, but lower than continues feed, where the Rialto 900MP with speed boost reaches 431 A4/min.

Production speed overview – SRA3 Based inkjet printers

| Baltoro HF | Brenva HD (with speed upgrade) | Canon Océ i300 | Canon Océ i200 | RISO Valezus | |

| Speed duplex A4/min | 275 (with speed license on A4 sheets) | 275 | 300 | 200 | 320 |

| Speed simplex A4/min | 197 (with speed license on A4 sheets) | 197 | 175 | 175 | 160 |

Speed is an important factor for a device choice, but so is quality for many users. The 1,200 x 1,200 native resolution of Xerox’ own W-series print heads is on par with the best inkjet production presses on the market today. Technically this is better than the Canon i300 resolution and far superior to the RISO printers, but judging quality is always in the eye of the beholder and needs to be judged by the output. Samples on uncoated and matte paper looked good and crisp. To bump up saturation the Baltoro can print in a “colour rendering mode” at somewhat reduced speed.

The second big area to watch out for is papers. While the top paper weight of 270 gsm is unchanged compared to the Brenva HD, the Baltoro will be able to print on standard coated offset paper– thanks to the high fusion ink used. High fusion ink is already available for the Trivor 2400 for users requiring coated paper. On the Baltoro the high fusion ink will be the only option for all types of papers. At the moment the number of certified papers is limited, but Xerox is busy certifying papers. Certified gloss coated papers will be available soon. No primer is required, which helps keeping the moisture content down and the drier compact.

The operator and colour control aspects sound very promising. According to Xerox an iGen operator can be retrained for the Baltoro within a week. Obviously, the press uses the tried and tested Freeflow workflow. The page wide array, already used in the top end colour toner models, is deployed in the Baltoro. It can take care of density fluctuations across the width and optimize the image automatically. Crucially it can detect missing nozzles as well, when a test sheet is printed. A built-in spectrophotometer allows for quick profiling and spot colour matching. In times when operators are becoming ever costlier and more difficult to come by automation will be a strong differentiator.

The Baltoro does replace the Brenva immediately. The Brenva had limited success globally as it targeted niche markets. It lacked in speed (at least initially, a speed upgrade came in 2018), in imaging resolution and support of coated paper. But it seems Xerox did its homework with the Baltoro.

Xerox is eager to point out that the Baltoro will be a platform. While this has been said about the Brenva and Rialto as well, Xerox is determined to enlarge the model range soon. A first look confirms that there is space for two more inkjet banks and ink containers. Picking the right choices will be crucial as a colour exchange will not be as easy and quick as on an iGen5 or Iridesse, where it can easily be done in 20 minutes. The low hanging fruit would be two inks for gamut expansion.

White, metallic and spot gloss could have more value add, although this might require other heads (larger drops) or ink systems (UV) to achieve the full potential. There are more potential paths however. A longer sheet size would be nice, as announced as option for the iGen5. Some speed upgrades could be possible, but this could mean lower density or require other feed & finish modules. Still some users would welcome the option. A lower spec version could even be more promising as the device is pricey, about the range of an iGen5. In any case, getting some more models out relatively quickly will be crucial to underscore the claim that the Baltoro is a platform. I hope and expect to see something at least at drupa 2020.

|

|

The Baltoro HF shows a lot of promise for a market that is likely to grow rapidly. To take advantage this requires a well-integrated and committed development team. Being able to use own inkjet heads gives Xerox more leeway in finetuning inks, head and paper interaction. Leveraging the iGen5 transport and an array of feed and finish solutions gives the system a head-start in integration and choice but might come with limitations in paper transport speed. Adding traditional Xerox strength in workflow, colour control and automation ensures high productivity and easy operability. The better integration comes at a price however with Xerox closing the former Impika site in Aubagne (France), which was acquired six years ago. All inkjet products are now designed and manufactured in Rochester.

On the Aubagne site closure Xerox states: “We are committed to our broad inkjet portfolio and are investing in production inkjet innovation to introduce new industry-leading capabilities such as the Baltoro HF Inkjet Press. We have initiated a project to sell or close the Aubagne site and centralise inkjet manufacturing within existing Xerox sites.” Xerox also stated that the company is ramping up R&D spend, accordingly we should expect more developments in inkjet and other technologies.

Leave a Reply