At the end of the road for heatset offset?

My career in print started almost 30 years ago at MAN Roland, the largest web offset manufacturer at that time. In 2001 I left the company to focus on digital print, also expecting that the market for ever-faster conventional presses would eventually dry up. MAN Roland eventually had to declare bankruptcy and was split into two companies. The web press portion later merged with Goss, one of its largest competitors. Still, sales declined and it seems that we are now at the end of the road for heatset offset.

At the recent Intergraf “Print Matters for the Future“ conference, I listened to a remarkable presentation on high volume flyer/door drop printing. On the background of major advertisers pulling out of printed door-drops and impeding governmental regulations that could essentially stop door drops the presentation was already quite interesting. The good news is that proposed regulations are still being reviewed and most retailers still stick with door drops (more on the preference of consumers for door drops here).

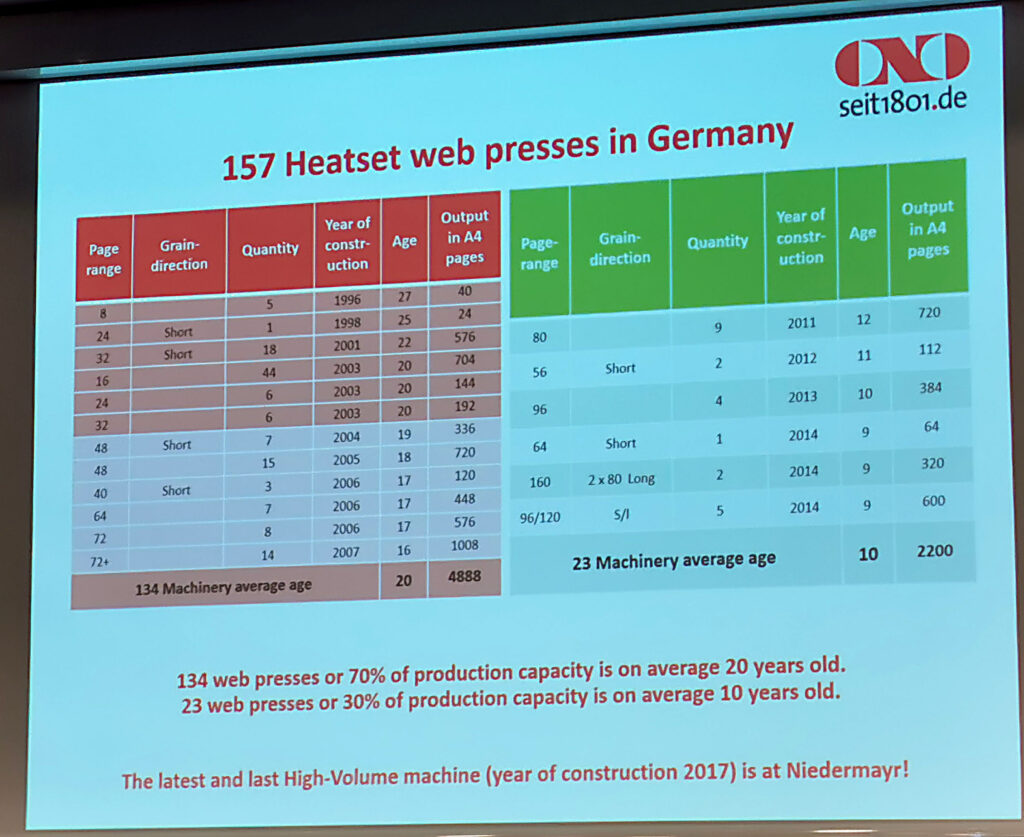

The presentation was held by Johannes Helmberger, owner of the German web offset printer Niedermayr Group. He has been tracking the heatset web offset market in Germany for years, being one of the largest heatset printers himself. What was new to me was that apparently the last high-speed (32+ pages) heatset web-offset presses were built in 2017 – the presses installed at Niedermayr among those. That means that 70% of the 157 heatset web offset presses in Germany are now on average 20 years old, while 30% of the base is on average 10 years old. As a result, the last heatset web press manufacturer manroland/Goss is supposedly up for sale.

The age of the presses has some ramifications. The older the press, the less competitive it is, especially in a tightening market. Waste and energy consumption is higher. Adhering to environmental regulations will get more complicated as well, like tracking energy consumption and exhaust monitoring.

Even if printing companies wanted to invest, this could be tough. There is not a lot of choice in manufacturers – although manroland can surely build another press. Financing will be more complicated as the reduction in web offset printers will mean every bank will look twice on a loan. Additionally, insecurity remains on the mineral oil content in heatset offset, which came under scrutiny lately.

Possibly we are at the end of the road for heatset offset. Productivity and cost per print can only be beaten by gravure in commercial print (which dropping out of the market at an even faster rate). Despite the cost advantages demand is moving in the other direction as web inkjet installations still keep increasing.

Leave a Reply